Welding in CT

Established in 1970, LABCO has 40 years of experience in welding in CT and fabricating in CT. We have joined countless products and materials, from minute weldments to very large fabrications weighing tons. Look no further than LABCO welding for all your welding in CT needs.

Utilizing these processes:

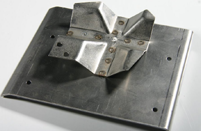

LABCO Welding is Connecticuts most versatile welder. We are a quality driven welding manufacturer, committed to the safety and growth or of our employees, and fully certified in all aspects of welding. Together with a combined experience of over 40 years in all aspects of welding and a large, modern facility, we offer you the craftsmanship and flexibility that it is very difficult to find anywhere else. TIG Welding in CT:Tungsten Inert Gas Welding (TIG welding) is an arc welding process that uses a non-combustible tungsten electrode to produce the weld. It is most commonly used to weld thin sections of stainless steel and non-ferrous metals such as aluminum, magnesium and copper alloys. This welding process grants the operator greater control over the weld than shielded metal arc welding and gas metal arc welding, allowing for stronger, higher quality welds. MIG Welding in CT:Gas Metal Arc Welding (MIG welding) is a welding process in which an electrical arc forms between a consumable wire electrode and work piece meta(s), which heats the heats the metals and causes them to melt and join. MIG welding is the most common industrial welding process, preferred for its versatility, speed and the relative ease of adapting the process to robotic automation. ARC Welding in CT:ARC welding is a type of welding that uses a welding power supply to create an electric arc between an electrode and the base material to melt the metals at the welding point. They can use either direct (DC) or alternating (AC) current, and consumable or non-consumable electrodes. The welding region is usually protected by some type of shielding gas, vapor, or slag. Arc welding processes may be manual, semi-automatic, or fully automated. First developed in the late part of the 19th century, arc welding became commercially important in shipbuilding during the Second World War. Today it remains an important process for the fabrication of steel structures and vehicles. Resistance / Spot Welding in CT:Resistance Welding - also known as "spot welding" or "resistance spot welding" - is a thermo-electric process in which heat is generated at the interface of the metal parts to be joined by passing an electrical current through them for a precisely controlled time under controlled pressure. Applications of resistance welding in CT are vast - ranging from tiny spot welds on implantable medical devices to welding the enormous bolts on residential or commercial water heaters. Both conductive and resistive materials may be joined using a resistance spot welder. Resistance welding power supply selection is based on a number of criteria including material, the presence of plating, geometry and size of the parts to be welded, whether you need a spot weld or seam weld, the need for data collection and/or monitoring, available input power at your facility, and desired production rate Speak to our team today at (860) 632-2625 for a free estimate or use our Contact Page for a quick response Related Projects |

|

We can process:

We can process: