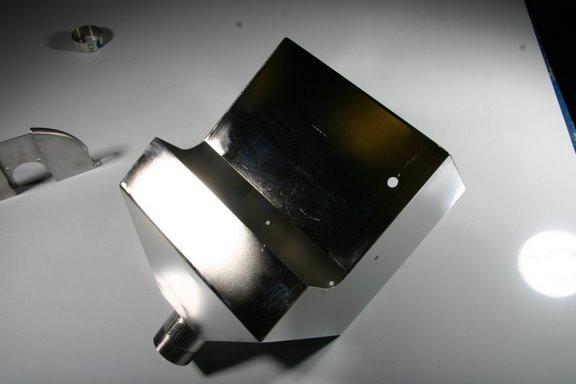

Precision Sheet Metal Fabrication in CTIf it's Precision Sheet Metal Fabrication in CT you need, LABCO Welding is the right company for the job.Sheet metal fabrication is using sheet metal to build metal machines and structures. It can be a complex process involving many different professionals. Stainless Steel Fabrication - 4" Round Transitioning to a 5" by 10" Oval. This custom pc has a hollow 1/8 x 1" high strip with a 90º fitting on the bottom

Custom 16GA Stainless Steel Fabrication

301 ½ hard Stainless Steel Bracket

Sheet metal fabrication generally involves cutting and burning the sheet metal. Special tools, such as band saws, are used to cut the sheet metal. Chops saws are also used in sheet metal fabrication. Sheet metal fabrication also involves the use of hydraulic breaks. With hydraulic breaks, sheet metal fabrication is simplified, as they help create bends at predetermined angles. Rolling machines are also used in sheet metal fabrication to form steel into round sections. Another main focus of sheet metal fabrication is welding. After the sheet metal parts are formed, they are assembled and tack welded into place. Various welding techniques can be used in sheet metal fabrication to avoid warping or other visual defects. These include using a stout fixture, welding in a staggered manner, covering the metal with sand during the cooling process, and special straightening processes. Straightening warped steel during sheet metal fabrication is accomplished with an Oxy-acetylene torch. With straightening, heat is applied to the metal in a slow, linear fashion. Using this method, a highly skilled welder can remove even significant warpage. To finish the sheet metal fabrication process, the metal is usually sand blasted, then primed and painted. Then, the finishing touches are placed according to the customer’s specifications, and the piece is inspected and shipped. Speak to our team today at (860) 632-2625 for a free estimate or use our Contact Page for a quick response. Related Projects |

|